Our Package includes Gas filtration and Separation Package, Water filtration package, Compressed Air filtration Package, Fuel oil filtration package, Hydraulic and lubricant oil filtration package and other skid mounted gas or liquid filtration packages

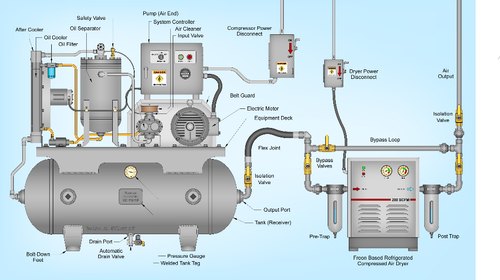

Air Dryer

Compressed air – and the right air dryer – will improve productivity, system efficiency, and product or process quality. Choosing the appropriate compressed air dryer and air compressor filter is very important for operating at your best. Whether you need a refrigerated air dryer, desiccant air dryer, or another air compressor filter or dryer system.

Filter Products

Vacuum Pump Exhaust Filters

Remove all visible oil mist from vacuum pump exhaust, even when it is saturated with oil. The exhaust gas may be recycled to the process or the pumps may exhaust into a clean work area, eliminating the need to run ductwork and exhaust pipes outside. The high efficiency filter cartridge continuously drains the collected liquid, allowing the user to recover expensive, inert lubricating fluid and resulting in extremely long filter cartridge life. Filters are available for pumps with flow ranging from 3 to 850 cfm.

Sample Analyzer Filters

Gas and Liquid Sample Analyzer Filters protect analyzers from sample impurities by removing solids and liquids from gases with 99.999% efficiency at 0.01 micron or lower. Composed of borosilicate glass microfibers with a resin binder, Balston sample filters are inert to most any gas or liquid.To satisfy the extremely wide range of requirements for analyzer sample filters, Parker Hannifin supplies a complete line of filter housings in stainless steel, polypropylene, and other corrosion resistant materials, as well as a choice of high efficiency filter elements which are inert to most all liquids and gases.

Sterile Air Filters

Compressed air is contaminated with compressor oil, water, condensate, pipe scale and rust. The warm, moist, oxygen-rich compressed air provides the perfect environment for bacteria to grow and prosper. This natural occuring contaminate can also effect the taste, appearance, and shelf life of food product. The food processing and packaging industry utilizes compressed air extensively throughout their facilities. In addition to packaging, compressed air is also used to push and propel product, and cut and mix product. Although most compressed air systems have some form of filtration, the filtration is not nearly adequate, particularly where bacteria and mold are concerned. Safeguard your food product from bacterial contamination with a Parker Balston Sterile Air Filtration System.

Sterile Air Filtration System will safeguard your operations from rust, pipescale, water, oil, and bacteria. These filters will remove contaminants at a very high efficiency – up to 99.99% for 0.01 micron particles and droplets. Liquid releases from the filter cartridge to an automatic drain as rapidly as it enters the filter. This allows the filter to continue removing liquids for an unlimited time without loss of efficiency or flow capacity. The final stage of filtration removes all viable organisms with an efficiency rating of 99.9999+% at 0.01 microns. Select 1/1” to 1” line filters are constructed of 304 stainless steel and are designed to hold up to the harshest environments. Parker Balston Sterile Air Filters are in full compliance with FDA requirements.

Steam Filters

Steam filters for hospitals eliminate instrument staining, spotting, and rusting caused by wet or dirty steam. Wrapped articles emerge from the sterilizer cycle drier and cleaner. Filtering hospital steam also results in reduced contamination of sterilizer interiors which in turn cuts down on cleaning time. Maintenance of sterilizer steam control valves, door seals, and other rubber materials is also significantly minimized.

Filtration and Separation Division

CDAS HL Medium Flow Heatless Compressed Air Dryer System

Medium flow compressed air treatment systems providing pressure dew points of -70°C, -40°C or -20°C at flow rates up to 300 m³/hr @ 7 barg. Suitable for all industrial compressed air applications.

OIL-X Compressed Air Filter (For Pressures up to 16 and 20 bar g)

High efficiency coalescing and dry particulate filters with very low pressure drop providing excellent energy savings.

Gas Generators

Provides on-site, on-demand gas supply solutions, and offers a comprehensive range of analytical and industrial gas generation systems. Our nitrogen gas generators for industrial applications and analytical lab gas generators support laboratory equipment and instruments. All Parker gas generators provide simple “plug and play” installation, efficiently enabling a continuous or on-demand supply of consistently pure gas.

PSA Nitrogen Generators

Nitrogen gas generators produce high purity nitrogen from compressed air, eliminating the inconvenience of delivered nitrogen supplies. Nitrogen can be produced at low dewpoints from nearly any compressed air supply. Our range is designed to continually transform standard compressed air into nitrogen at safe, regulated pressures by utilizing pressure swing adsorption (PSA) technology. Our nitrogen gas generators are suitable for use in a variety of applications, serving across many of today’s major industrial markets including manufacturing, tire inflation and analytical instrument applications.

Hydrogen Gas Generators

Hydrogen gas generators are available in a wide selection of models and configurations. We offer the ultimate combination of safe operation, reliability, high performance, and low cost of ownership. Our hydrogen generators produce a continuous flow of high-purity and ultra-high-purity hydrogen from de-ionized water and electricity. All of our hydrogen generators meet industry standards and are suitable for use in a wide range of applications and markets.

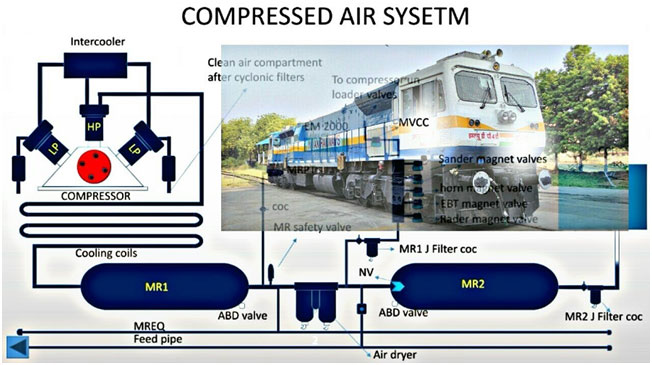

Railway Compressed Air Filters

Filter Elements

The filter element is the central component of industrial filters. The actual filtration process takes part in the filter element. The main filter variables, such as retention capacity, dirt holding capacity and pressure loss are determined by the filter elements and the filter media used in them.