Piping Valves

Valve package from internationally renowned manufacturer of industrial valve certified products are approved & used worldwide in oil &gas , power, chemical & petrochemical industries.

Our valves offered in size ranging from 1/2” to 48” Services applicable for the valves are:

Pressure class upto 2500Lbs: and additional upto 10,000PSI for API 6A valves

TPC offers valve range that is with various operator options manual or hand wheel, gear, electrical actuator, pneumatic actuator & G/O actuated etc.

Material – Carbon steel, Stainless steel, Brass, Ductile iron, Alloy steel & Exotic materials (Monel, Inconel, Duplex, Super Duplex)

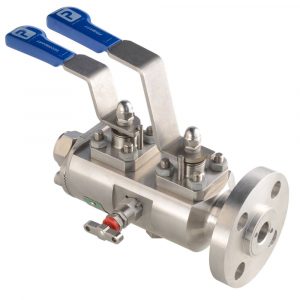

Trunnion Ball Valve

Trunnion ball valves are offered in 2 PC side entry, 3 PC side entry, welded body and top entry design in a wide range of carbon, stainless steel, duplex stainless steel, alloy and other special materials. FBV trunnion ball valves are manufactured according to API 6D Design and fire safe tested per API 6FA and API 607 Standard.

PRODUCT RANGE

Sizes NPS 2 to NPS 48

Class 150 to Class 2500

MATERIALS

Available Forged (A105, A182 F304, F304L, F316, F316L, F51, F53, A350 LF2, LF3, LF5,) Casting (A216 WCB, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2) Monel, Inconel &Hastelloy.

Butterfly Valves

Butterfly valve is a valve used for flow regulation in large pipe diameters in which the disc takes the form of disk. Operation is similar to that of a ball valve. A plate or disc is positioned in the center of the pipe. The disc has a rod passing through it that is connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

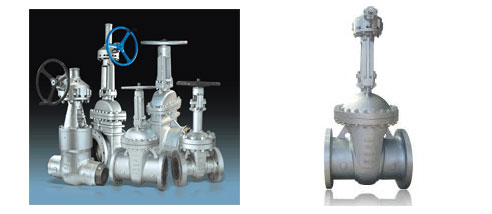

Gate Valves

Sizes NPS 2 to NPS 48. Class 150 to Class 2500. Full or Reduced Bore. RF, RTJ, or BW. Outside Screw & Yoke (OS&Y), rising stem. Bolted Bonnet or Pressure Seal Bonnet. Flexible or Solid Wedge. Renewable seat rings.

MATERIALS

• Available in Casting (A216 WCB, WC6, WC9, A350 LCB, A351 CF8, CF8M, CF3, CF3M, A995 4A, A995 5A, A995 6A), Alloy 20, Monel, Inconel, Hastelloy

DESIGN STANDARD

• Design & manufacture according to API 600, API 603, ASME B16.34

• Face-to-face according to ASME B16.10

• End Connection according to ASME B16.5 (RF & RTJ), ASME B16.25 (BW)

• Test & inspection according to API 598

• Also available per NACE MR-0175, NACE MR-0103, ISO 15848, API624

Check Valves

Wafer check valves, also known as dual-plate check valves, have two spring loaded half-moon shaped discs that rotate about their shaft. The disc plates are kept shut by a torsion spring. When fluid flows in a forward direction, the pressure of the fluid causes the disc plates to swing open, allowing flow. The check valve is closed by the spring as soon as flow ceases, before any reverse flow can occur.

API 6D Pipeline Valves

API 594 Check Valves: Flanged, Lug, Wafer and Butt-Welding

ASME B16.34 Valves Flanged, Threaded and Welding Ends

ASME B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2 through 24

ASME B16.47 Series A Large Diameter Steel Flanges: NPS 26 Through NPS 60 Metric/Inch Standard

ASME B16.25 Buttwelding Ends

ASME B16.10 Face to Face and End to End Dimensions of Valves

MSS SP-25 Standard Marking System for Valves, Fittings, Flanges and Unions

Size Available

NPS 2 to NPS 24 (DN50 to DN600)

Pressure Rating Available

Class 150 to Class 900

Double Block Bleed Valves

- Monoflange Process to Instrument Valve

- Modular Valve - ProBloc Series

- Modular valve - Probloc® TP Series

Monoflange is designed to replace conventional multiple-valve installations currently in use for interface with pressure measuring systems in process control applications.

Valve Type

OS & Y, Needle Valve

Configuration

Block-Block-Bleed, Block-Bleed

Materials of Construction

316 Stainless Steel, Carbon Steel, Duplex

Flange Size

1/2, 3/4, 1, 1-1/2, 2 inch

Flange Face Type

Raised Face Spiral, Ring Type Joint

ANSI Flange Class

150, 300, 600, 900, 1500, 2500

Connection Size

1/2 (NPT F) inch

Vent Plug Thread Size

1/4 NPT F inch

Seal Material

PTFE, Graphoil

Handle Type

Stainless Steel Lever

Specifications Met

N/A, NACE, Fire Safe

API 6A, API 607, PRL 2, PSL 2, PSL 3, PSL 4, TAMAP, MESC SPE 77/312

Maximum Operating Pressure

275, 720, 1440, 2160, 3600, 6000, 285, 740, 1480, 2220, 3705, 6170, 290, 750, 1500, 2250, 3750, 6250 psi

19, 50, 99, 149, 248, 414, 20, 51, 102, 153, 256, 426, 52, 103, 155, 259, 431 bar

Maximum Operating Temperature

204, 538 °C

400, 1000 °F

Minimum Operating Temperature

-29, -54 °C

-20, -65 °F

Industry Application

Instrument Isolation, In Situ Calibration, Inline Process Isolation, Chemical Injection, Process Sampling

ProBloc series is designed to replace conventional multiple-valve installations currently in use for interface with pressure measuring systems in process control application

Bore Diameter

20, 15, 10, 25, N/A mm

Materials of Construction

316 Stainless Steel, Carbon Steel, Duplex

Valve Configuration

Flange x Screw

Configuration

Ball-Needle-Ball

Flange Size

1/2, 3/4, 1, 1-1/2, 2 inch

Flange Face Type

Raised Face Spiral, Ring Type Joint

ANSI Flange Class

150, 300, 600, 900, 1500, 2500

Connection Size

N/A, 3/4 (NPT F), 1/2 (NPT F), 1 (NPT F) inch

Seat Material

PEEK, PTFE, PHLEX

Handle Type

Stainless Steel Lever

Specifications Met

N/A, NACE, Fire Safe

API 6A, API 607, PRL 2, PSL 2, PSL 3, PSL 4, TAMAP, MESC SPE 77/312

Maximum Operating Pressure

275, 720, 1440, 2160, 3600, 6000, 285, 740, 1480, 2220, 3705, 6170, 290, 750, 1500, 2250, 3750, 6250 psi

19, 50, 99, 149, 248, 414, 20, 51, 102, 153, 256, 426, 52, 103, 155, 259, 431 bar

Maximum Operating Temperature

232, 204 °C

450, 400 °F

Minimum Operating Temperature

-29 °C

-20 °F

Industry Application

Instrument Isolation, In Situ Calibration, Inline Process Isolation, Chemical Injection, Process Sampling

Pro-Bloc® TP series trunnion mounted valve with a low operating torque is available with either soft or metal seat options for bubble tight sealing, spanning a wide range of pressures and temperatures.

Seat Type

Trunnion Mount

Bore Diameter

15, 25, 38, 50 mm

Valve Configuration

Flange x Screw, Flange x Flange

Configuration

Ball-Needle-Ball

Materials of Construction

316 Stainless Steel, Duplex, Low Temp Carbon Steel, Alloy 625, Alloy 825

Flange Size

3/4, 1, 1 1/2, 2, 3, 4 inch

Flange Face Type

Raised Face Spiral, Ring Type Joint

ANSI Flange Class

150, 300, 600, 900, 1500, 2500

Connection Size

1/2" NPT F, 1" NPT F, 1/2" A-LOK, 1" A-LOK, 1/2" CPI, 1" CPI, 12mm A-LOK, 25mm A-LOK, 12mm CPI, 25mm CPI

Seat Material

PTFE, TFM, PEEK, Metal

Specifications Met

Fire Safe, NACE

Maximum Operating Pressure

6,000 psi

414 bar

Maximum Operating Temperature

360 °C

680 °F

Minimum Operating Temperature

-196 °C

-321 °F

Packing Material

Graphite

Shut-Off / Pigging Valves

Shut-Off Pigging Valve (SHPV), also known as a Trunnion Block-Mounted Ball Valve, with state-of-the-art ease-of-use and performance under the severest conditions. Shut-Off Pigging Valve reduces torque and stem loading while adding longer life. SHPV is bi-directional and, you can use it as a launcher, receiver, or catcher. You can install this pigging ball valve can with a by-pass where needed.

Design

• Engineered, manufactured and tested to API 6D

• Industry Standards: API 6D, ASME B16.34 and API 598

• Meets NACE MR0175-03

• Size range: 2” – 16”

• Pressure Classes: ANSI Classes 150 to 1500

• Standard temperature range: -20 to 300 deg. Fahrenheit

• Special Order range: -50 to 400 deg. Fahrenheit

• Materials: LF2, 316 SS, and Exotic Alloys as required

• Seals: HSN, HNBR, James Walker, Viton, Teflon, Devlon Peek or as required

Features

• Positive Shut Off

• Trunnion Block mounted Ball for reduced torque and stem loading

• Large Bearings for smooth robust operation

• Up Stream sealing with automatic downstream cavity relief

• Double Block and Bleed with vent and drain capabilities

• Large button head grease fittings with buried checks

• Emergency seat sealant injection

• Pig Entry Cap with vent

• Pig Entry Cap with hex drive and spanner drive options

• Open and Closed lockable stop plates 2” – 6”

• 6” and larger utilize a body cavity equalization valve

• Large Actuator Mounting Pads and Stems

• Accepts Bullet, Spherical, and Double-Dish pigs

• Pigs are fabricated to fit all pig valves.

Benefits

• Trunnion Block design offers reduced torque and robustness

• Complete Range of Fluid flexibility and compatibility

• Cost savings over conventional pigging systems and skids

• Available as a Launcher, Receiver, or Catcher.

• Forged construction reduces NDE requirements

• Complete selection of pigging systems and accessories